Different kinds of direct drive compressors made by Sharoo

37 KW

- Electro-Motor : 37 KW

- Production air volume: 5000 lit/min

- Working pressure: 10 Bar

Price : — Euro

30 KW

- Electro-Motor : 30 KW

- Production air volume: 4200 lit/min

- Working pressure: 10 Bar

Price : — Euro

15 KW

- Electro-Motor : 15 KW

- Production air volume: 2500 lit/min

- Working pressure: 10 Bar

Price : — Euro

7.5 KW

- Electro-Motor : 7.5 KW

- Production air volume: 1000 lit/min

- Working pressure: 10 Bar

Price : — Euro

132 KW

- Electro-Motor : 132 KW

- Production air volume: 19000 lit/min

- Working pressure: 10 Bar

Price : — Euro

90 KW

- Electro-Motor : 90 KW

- Production air volume: 15000 lit/min

- Working pressure: 10 Bar

Price : — Euro

75 KW

- Electro-Motor : 75 KW

- Production air volume: 11200 lit/min

- Working pressure: 10 Bar

Price : — Euro

55 KW

- Electro-Motor : 55 KW

- Production air volume: 8000 lit/min

- Working pressure: 10 Bar

Price : — Euro

315 KW

- Electro-Motor : 315 KW

- Production air volume: 50000 lit/min

- Working pressure: 10 Bar

Price : — Euro

250 KW

- Electro-Motor : 250 KW

- Production air volume: 44000 lit/min

- Working pressure: 10 Bar

Price : — Euro

200 KW

- Electro-Motor : 200 KW

- Production air volume: 28000 lit/min

- Working pressure: 10 Bar

Price : — Euro

160 KW

- Electro-Motor : 160 KW

- Production air volume: 22000 lit/min

- Working pressure: 10 Bar

Price : — Euro

What is a screw compressor?

The screw compressor is one of the most common compressed air production devices, the way it works is as follows:

After the device is turned on, the ambient air first passes through the air filter and enters the air conditioner unit. In the air conditioner, there are two spiral rotors in the shape of a male and a female, which rotate alternately with a very small distance and slack. are, the air in this section after entering the compressor is trapped in the space between the two spirals and the shell, and then due to the continuous volume reduction, the kinetic energy of the air molecules increases and compression takes place. The increase in pressure in screw compressors starts from one side, and at the end of the spirals, the compressed air comes out along with the oil, and after the oil is separated from the compressed air by the separator filter, the output air is stored in the compressed air tank after passing through the aftercooler. is made

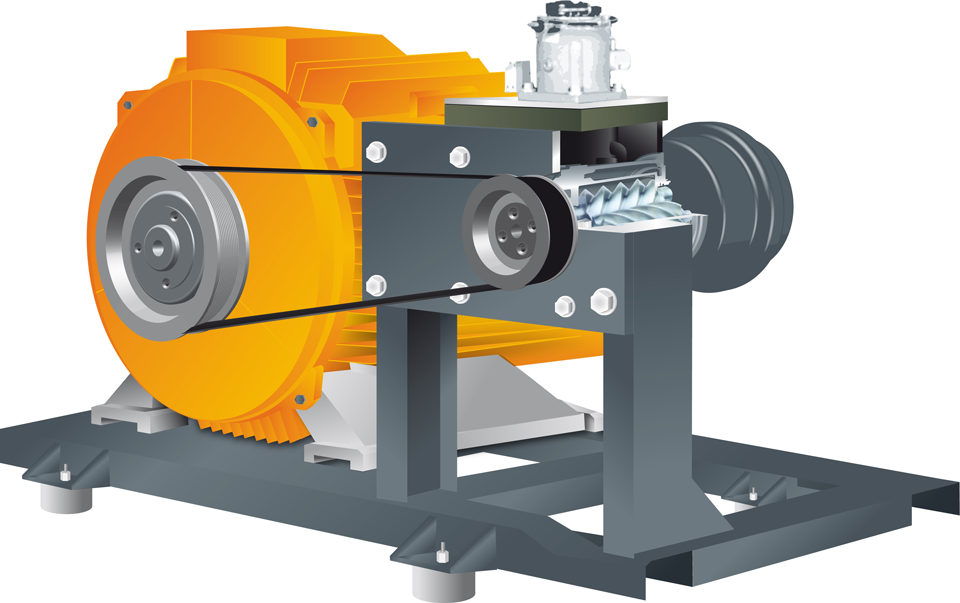

Two common methods for assembling screw compressors

The assembly and construction of screw compressors can generally be divided into two categories: direct screw drive compressors and belt screw drive compressors. The difference between these two direct drive and belt drive compressors is actually in their power transmission system, which the best compressors in the world have designed and built direct coupling air compressors due to the increase in the life of the device.

Why direct drive compressors?

- Due to the absence of a belt, no radial force is applied to the bearings of the electric motor and the airend, and it increases the lifespan of the compressor.

- Unlike the belt drive compressors, which over time due to the shifting of the pulleys causes an axial force in the airend, and the application of this axial force to the bearings of the airend causes the air conditioning unit to lock, in direct drive compressors, this state will not occur.

- Due to the lower number of vibrating parts, the direct drive system will have a lower level of noise pollution than similar systems.

- Having fewer rotating parts in this system means less failure of the direct coupling system. In other similar systems, due to the increase in the working time of the belt or creating tension in the rotating parts (such as pulleys), more failure is observed.

What are the advantages of the compressor manufactured by Sharoo Turbo Compressor Engineering Group?

- Very low noise and vibration with the low speed of the airend, higher efficiency than the belt series.

- The central hub is made with precise machining for permanent and accurate alignment of the electric motor and the airend. As a result, not needing clock and re-alignment of couplings in repairs is one of the advantages of this series of compressors.

- The quality and resistance of the coupling elastomer guarantees its smooth operation and long useful life.

- Acordoni steel hose for oil and air is resistant up to 225 degrees Celsius.

- In desert climates or environmental conditions with high temperature, one stage OVER SIZE air and oil radiator or high efficiency water chiller is used.

- The service life of bearings and felt bowls increases significantly due to the removal of the radial force of the belts.

- According to the standard, flexible connection is used in all the pipings connecting dynamic to static equipment.

A view of Sharoo Kompressor D series direct drive compressors

Why choose screw compressors equipped with VSD drive or variable frequency:

The most important reason for using VSD variable frequency screw compressors is to adjust the compressor speed based on the amount of air consumption and as a result significantly reduce energy consumption. In all compressors equipped with VSD, the amount of air production is precisely controlled according to the needs of the consumer by changing the frequency of electricity and as a result by controlling the speed of the electric motor. It is for use in various industries.

In this model, with the installation of VSD drive made in European countries (Fland, Italy and Sweden), it guarantees maximum saving in electricity consumption and energy storage up to 35%, no high starting current like star and triangle, slow and smooth starting, no loss Energy in no-load mode, reducing the sound of the device, increasing the useful life of the device up to 2 times.

"Sharoo Turbo Compressor Engineering Group" guarantees the following by installing VSD drives made in European countries (Fland, Italy and Sweden):

- Maximum savings in electricity consumption and energy saving up to 35%

- Absence of high starting current such as star and triangle.

- Smooth and quiet start-up without introducing sudden loads to the bearings of the electric motor and airend.

- No loss of energy in no-load mode.

- Great reduction in device noise

- Increase the useful life of the device up to 2 times

- Going to sleeping status automatically when the air consumption is low.

Features of the VSD drive made in European countries (Fland, Italy and Sweden) used by Sharoo Compressor:

• DC-bus dynamic control technology

• Built-in PLC for position control

• PID control

• Auto Reverse feature when the PID output is negative.

• Torque Control

• Has an internal chopper up to 30kW

• High speed pulse output

• Setting the output frequency from 0Hz to 320Hz

• Has internal digital potentiometer

• Ability to control multiple speeds

• Ability to reduce noise with carrier frequency up to 16kHz

• The possibility of setting and controlling the parameters of up to 2 different engines

• Automatic calibration of engine parameters

• The ability to accept several programs in order to increase and decrease the speed gradient