PSA Nitrogen Generator

Pressure Swing Adsorption (PSA) type Nitrogen Generation system that is used to separate and enrich Nitrogen from Oxygen employs CMS (Carbon Molecular Sieve) for adsorbent. Carbon Molecular Sieve (CMS) adsorbs Oxygen and Water Vapor molecules under certain pressure while allowing Nitrogen to pass through. The Nitrogen Generator consists of two adsorber vessels filled with CMS, a valve assembly, air filters, main pressure regulator, and a product receiver tank. Clean and dry air is directed to one of the adsorber beds where oxygen and water vapor is adsorbed faster than nitrogen in the pore structure of the CMS, thus increasing the nitrogen purity of the product gas stream to the desired level (95-99.999% as required by customer). This product flows out from the top of the adsorber bed, through the valve and into the product receiver at a pressure slightly below the feed air pressure.

PSA Nitrogen Generator Applications

- Petrochemical

- Oil industry

- Metal industry

- Chemical industry

- Plastic industry

- Production process and storage of food

- Charge nitrogen gas in tires

PSA Nitrogen Generator Features

- Simple structure, compact design, full automated operation

- Touch Screen PLC for controlling the complete system

- High performance, Rapid start-up and safety system, Minimum maintenance cost

- Superior silencer design gives low noise levels

- – Durable piston valves for long-life operation

Technical Specifications

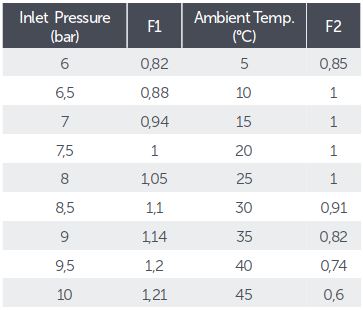

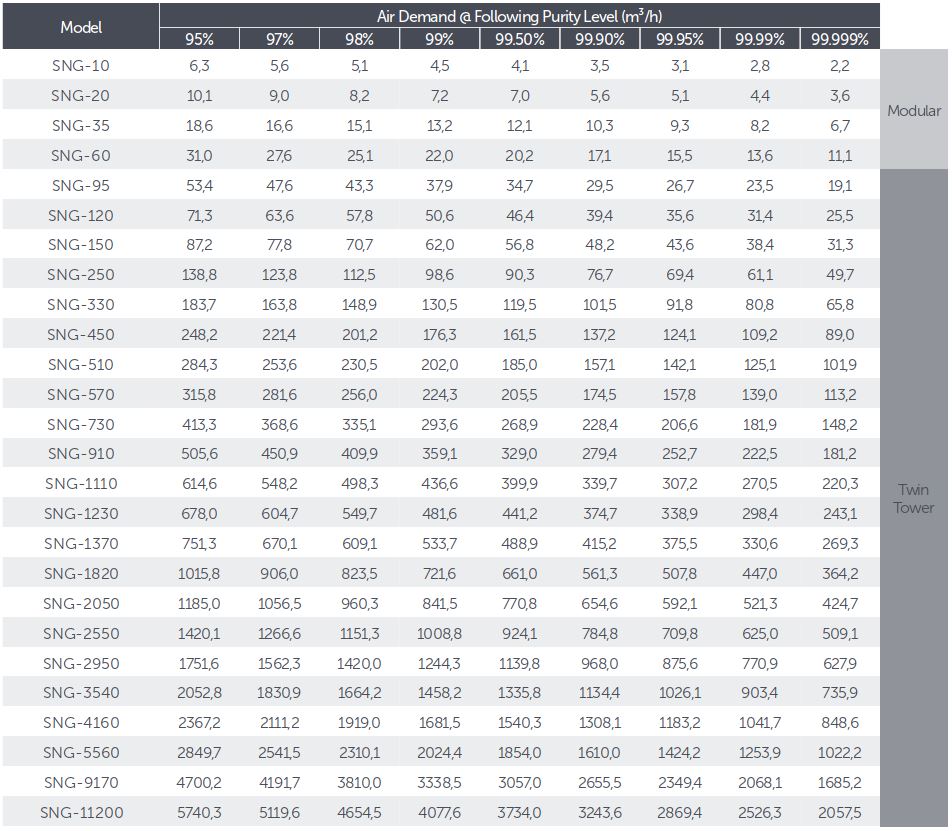

Air Demand - Following Purity Level (m³/h)

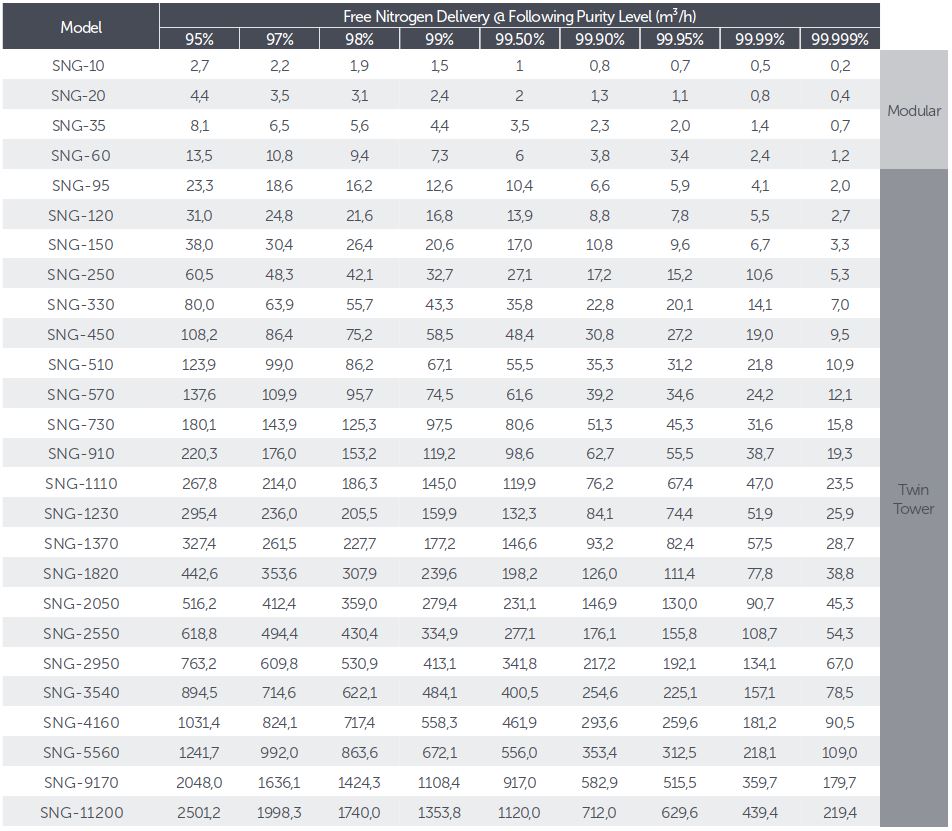

Free Nitrogen Delivery - Following Purity Level (m³/h)

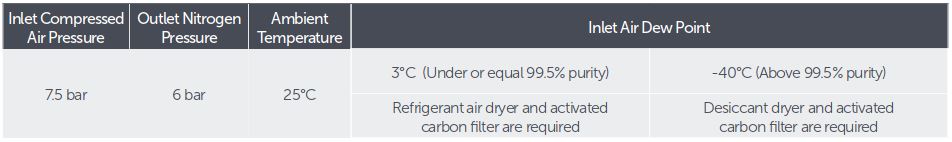

Reference Conditions

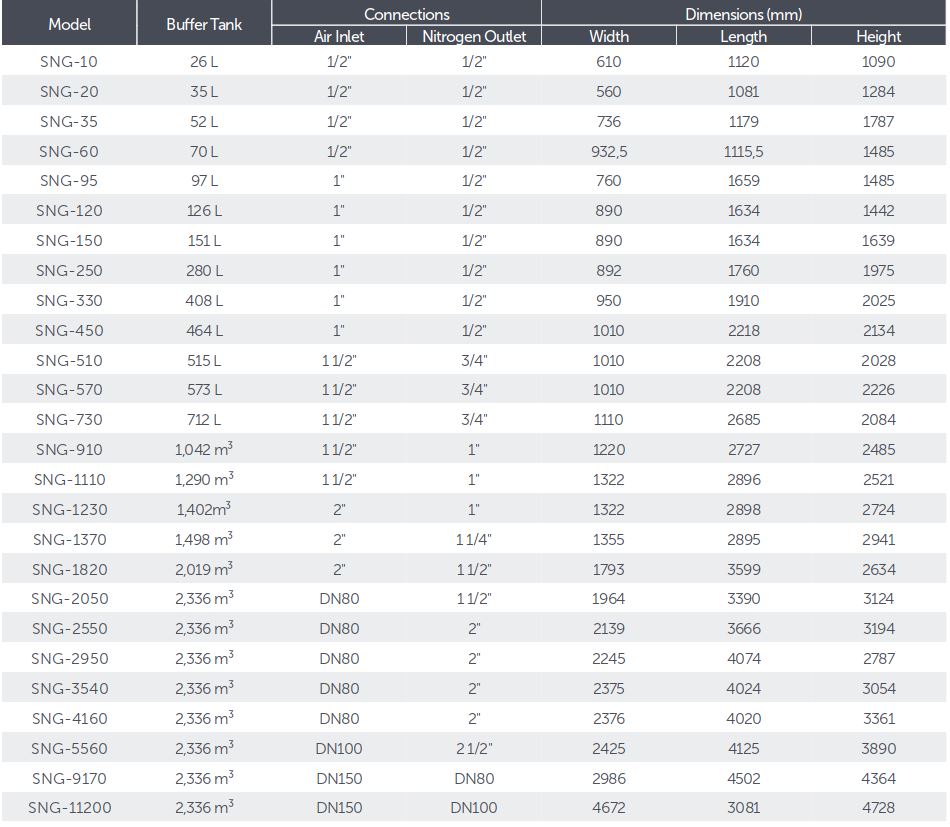

Structure Details

Correction Factor