Refrigerated Air Dryer

Micropor Refrigerated Air Dryer

Sharoo Compressor Refrigerated Air Dryer

What is refrigeration dryer?

There are several methods to separate water and moisture from the compressed air produced in the industry, and the use of a refrigeration dryer is one of the best and most cost-effective methods. If

What is the reason for moisture in compressed air?

The air produced by the compressor is about 20-30 degrees warmer than the ambient air, and the air produced in the tank slowly cools and the air vapor turns into water, and it carries a significant amount of water particles, oil and other impurities. Especially the water vapor that may condense in the compressed air and then enters the air distribution line and causes serious oxidation, corrosion and damage to the production line equipment. For avoiding you must use a refrigeration dryer.

Refrigerated dryers cover the needs of customers well and are one of the choices of many reputable companies. One of the most important property of the refrigeration dryer is the ease of installation and maintenance of the device. This advantage is such that there is no need to buy a microfilter anymore, and a person can open and close the parts or change them by him/herself without the help of an expert.

What is the usage of refrigeration dryer?

– By removing moisture and reducing the temperature of the air from the compressor, the refrigeration dryer allows the proper air to enter.

– The refrigeration dryer has a very simple operation system.

– These devices are installed as a converter between the compressor and the air inlet to the hall and purify the air entering the hall.

– For all devices, air with moisture is like poison. Air humidity and water particles in it cause metal parts to corrode and reduce their lifespan.

– On the other hand, in food factories or cold stores, the entry of water and moisture causes food and fruits to spoil, and for this reason, it is very necessary to use a refrigeration dryer.

– In general, the refrigeration dryer is useful in all places that use an air compressor system for air conditioning. But due to the sensitivity in some places, there is a greater need to install them.

What are the important parameters in choosing this type of dryer?

- Capacity and air flow rate produced by the compressor

- Ambient temperature and humidity around the compressor

- The inlet temperature of the air compressed by the compressor into the dryer

- Compressor working pressure

Installation conditions:

- Refrigeration dryer is installed after the compressor; Considering this issue, it is important to place the compressor in a covered space away from dust and sunlight, then place the dryer near the compressor.

- If you want to increase the efficiency of the system, consider the capacity of the dryer to be 20% (at least) more than the capacity of the compressor, so that when the temperature increases, the capacity of the dryer also increases and can bring the air to the dew point.

- You should also pay attention to the temperature of the environment where the dryer is placed; The temperature of this environment should be between 7 and 45 degrees and it is also important that the temperature of the compressed air entering the dryer is less than 50 degrees Celsius.

- When installing, pay attention to the distance of the dryer; This distance should not be more than 60 cm.

- Be careful not to open the legs of the device because these legs have the role of foundation and shock absorber.

- Protect this device from environmental cooling and heating for more efficiency and longer useful life.

- Cooperate with an expert during the installation or if you are going to install it yourself, carefully follow the steps mentioned in the guide and make sure that the connections are installed correctly.

- When buying equipment, pay attention to the selected material and use stainless or PVC pipes suitable for outlet connections.

- Finally, pay attention to the water trap; This should be installed between the compressed air storage tank and the refrigeration dryer.

Care tips:

- Refrigerated dryer condenser should be cleaned two to three times a week using air with appropriate pressure.

- Do not change the initial settings of the device without coordination.

- The ambient temperature of the house compressor should be controlled continuously.

- The microfilter used in the refrigeration dryer has an allowed operating time of 6 months or 5000 hours, and it is recommended to change it immediately after this time.

- Check that the drain hose is not kinked so that the refrigerant dryer exchanger does not get flooded.

Introduction to DEW POINT in refrigeration dryer

A certain working temperature and pressure of water vapor is called dew point, and in the compressor, when the output compressed air reaches the dew point, the steam in it appears as water droplets on the parts and often causes problems in the producing lines.

To completely remove moisture and prevent it from entering the system and pneumatic equipment, a device called a refrigeration dryer (compressor air dryer) is used. Our suggestion for maximum removal of moisture from compressed air is to use a refrigerated dryer, which is one of the best manufacturers of refrigeration dryers in the world.

Refrigeration dryer components

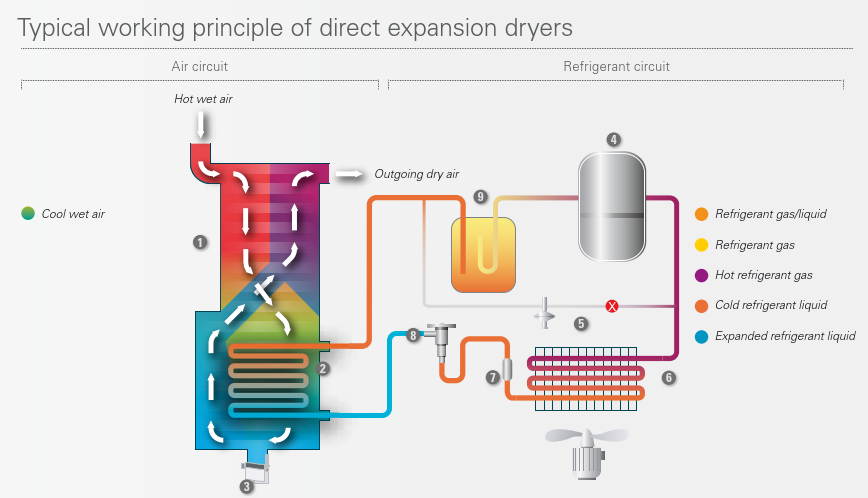

Refrigeration dryer components include the device’s compressor (motor), intelligent controller system, converter condenser, gas, valves and cabin and filters, which we will get to know more about some of these components in the following.

Also, refrigeration dryer components include refrigeration dryer compressor, condenser (systems with heat or temperature condensing, which is the condensing of a substance from gas to liquid, which is done in the form of cooling), heat exchanger, which is a device that transfers heat energy. It provides several fluids at different temperatures (Heat Exchanger), receiver, capillary tube and gas valve become a heat exchanger (Heat Exchanges Expansion Valve).

How to choose the right size of refrigeration dryer?

The first thing to pay attention to when choosing a refrigeration dryer is the ratio of the size of the dryer to the capacity of the compressor, and if a dryer is selected for a system and it is smaller than the size we need, the efficiency of the system will be greatly reduced due to overheating of the dryer. The action of removing moisture is not done completely. Therefore, it can be concluded that the size of the dryer can play a significant role in the dehumidification efficiency of the compressor.

In order to choose the best size of refrigeration dryer suitable for the compressor capacity, the most important factor that you should consider is the air production capacity of the compressor, and also things like the inlet air temperature and the ambient temperature are also effective in choosing a refrigeration dryer.