Compressed air tank

The main function of the compressed air tank is to store the compressed air by the airend…

What are the advantages of a compressed air tank?

1. The use of a compressed air tank significantly reduces the number of times the air compressor is turned on and off and the time it is under load, and for this reason, the useful life of the compressor and its accessories increases.

2. The high cross-sectional area in the air storage tanks reduces the temperature of the compressed air and causes the moisture in the air to be separated in the storage tanks and removed from the tank through the drain valve.

3. In the compressed air storage tank, pressure fluctuations are reduced to the ready existence in the compressor and during continuous operation, it keeps the air pressure constant.

Features of Sharoo compressed air tanks

- Design based on ASME SEC VIII standard

- Along with complete accessories:

1. Automatic emptying

2. SAFETY VALVE according to the size of the tank

3. WIKA brand pressure gauge

4. Gas valve

5. It has manhole

- Ability to provide working pressures of 8 Bar – 10 Bar – 13 Bar

- The design pressure is 10% more than the working pressure

- Hydrostatic test up to 1.5 times the design pressure

- Performing non-destructive UT-PT and RT tests upon request

- Internal epoxy thickness 90 to 150 micrometers

- External surface color up to 90 micrometers thick

- Welding tanks with special electrode 7018 according to ASME standard

- Design of resistant foundations for maximum stability

- The ability to install various types of automatic discharge (temporary, with float, with sensor)

- Ability to design and provide surge tanks (SURG TANK)

- The construction stages can be visited at each stage

- The ability to receive the color code (RALL) of the external surface upon request

- Design and construction based on materials:

Made of SA516-Gr70 according to ASME standard

IS-2062/ST37-2 / SA 516/IS-2002/SS 304/SS316

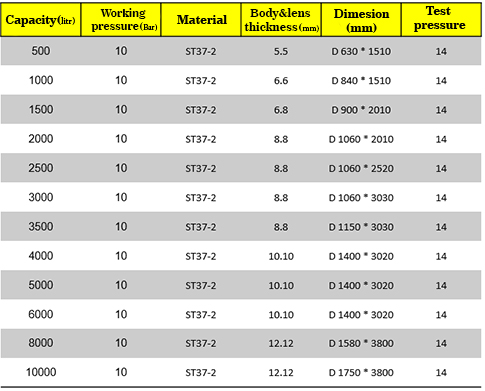

Information table of standard compressed air reservoirs of Sharoo Turbo Compressor