What is Oil Free Compressor?

An oil free compressor is an air production device that produces compressed air without using oil as a coolant. In normal models, oil is used to soften the parts and reduce wear.

The presence of oil inside the various parts of the compressor causes some oil to be present in the final compressed air. This impurity is not acceptable in any way for sensitive industries such as food and dentistry.

For this reason, new models of compressors have come to the market that work without oil, and thus their final product is free of oil.

Oil free compressor, single screw with 100% OIL FREE direct water spray technology:

- The new generation of oil-free air conditioner, with high technology and isothermal design:

“Sharo Turbo Compressor Engineering Group” has started to manufacture 100% oil-free compressors with its scientific colleagues in Europe to meet the needs of the food and pharmaceutical industries.

- This group offers consumers an 18-month unconditional warranty for airend.

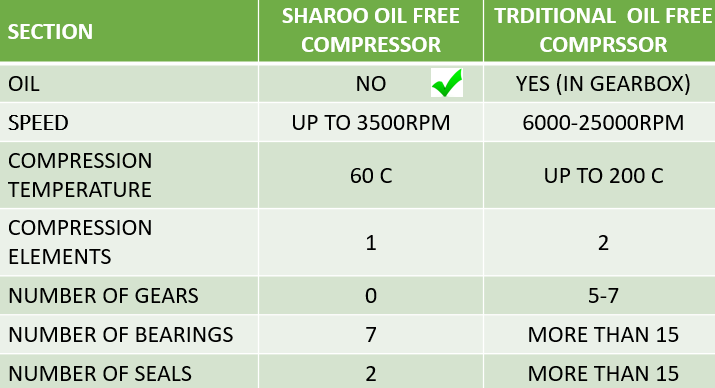

- The new generation of oil-free compressors does not have gears to increase speed. Therefore, there is no concern about oil leakage from the gearbox of the old generation oil-free compressors to the airend.

- These compressors are designed as direct drive with a 1:1 drive ratio.

- The sound of the device is minimal due to the direct drive and the low speed of the new generation oil-free compressor.

- It has maximum thermal efficiency due to cooling by water and tending to isothermal condensation (constant temperature).

- Providing after-sales services to all parts of Iran.

Why Sharo Camp single screw OIL FREE compressors:

- There is no oil in the oil free water injection compressor, but there is a lot of oil in the gearbox compartment in the double stage compressors. Due to the high screw speed of 25,000 rpm (more than 400 rpm) and the high heat of the device, there is a possibility of early mechanical failure of the seal and the oil leaks into the air chamber and mixes with the exhaust air.

- The maximum speed of the oil-free compressor with water injection technology is up to 3500 rpm. This value in double-stage compressors, the second stage reaches 25,000 rpm, which causes more dynamic and radial loads to be applied to the bearings.

- The compressors are in full dynamic load balance and no axial loads are applied to the bearings.

- The output temperature of the oil-free compressor with water injection technology reaches a maximum of 60 degrees Celsius and is completely similar to the isothermal diagram and the maximum thermal efficiency, but in double-stage compressors, the temperature tends to more than 200 degrees Celsius, which causes Premature failure of consumable parts, o-rings and seals.

- The oil-free compressor with water injection technology compresses the air in one step, but in the double-stage compressor, the process is done in two steps, as a result, it requires more moving parts.

- Oil-free compressors with water injection technology do not have timing gears. Meanwhile, old generation double stage compressors have 5 to 7 gears. Therefore, it needs oil for lubrication and there is a possibility of oil leakage to the airend.

- There are 7 oil-free compressor bearings with water injection technology. This number is more than 15 in double-stage compressors, which increases the cost of repairs and overhaul, and due to the high speed of the compressor, the useful length of the bearings is less.

- There are 2 seals and mechanical seals in the oil-free compressor with water injection technology. This number is more than 15 in double stage compressors.

- If two-stage compressors are not used for a long time, the Teflon coating on the screws will become long and flaky over time. As a result, a lot of damage is done to the airend, and during startup due to the loss of slack (Internal Clearance), they get a big pressure drop.

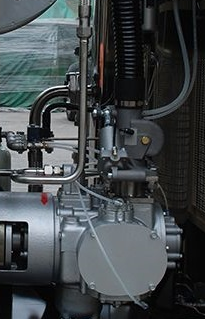

Air conditioner unit – connections and piping:

All the connections – piping and the airend are made of stainless steel alloy, which guarantees non-corrosion, non-pollution and high reliability.

Commend circuit:

All contactors from the world’s famous brands ABB – Schneider – LS are installed on the device to increase confidence and peace of mind.

By installing VSD drives made in European countries (Fland, Italy and Sweden), this company guarantees maximum savings in electricity consumption and energy savings of up to 35%.

In addition, the absence of high starting current such as star and triangle, smooth and quiet start-up, no loss of energy in no-load mode, reduction of device noise, and 2-fold increase in the useful life of the device are also guaranteed.

Centrifugal fan:

It has a much stronger structure than axial fans. Along with higher static pressure. Better dynamic balance and guaranteeing the absence of vibration and noise of the device. The blades of this fan include better aerodynamics, so it consumes less electricity for the same flow rate as axial fans.

100% oil-free compressor, with 18-month unconditional warranty, airend with the latest water injection technology.

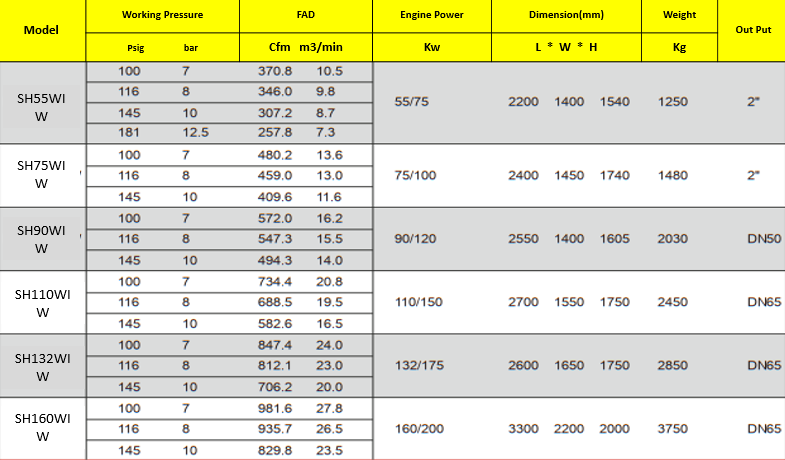

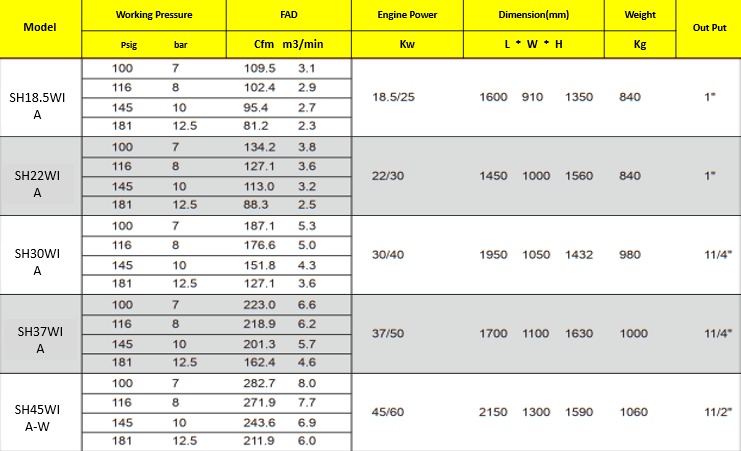

Information table of Sharoo Compressor oil-free compressors